The idea for a better leash was formed over many trail runs with our dogs. Conventional leashes are slow to attach and detach, they’re cumbersome and annoying to carry when your dog is off leash, and they go between your dogs legs and sometimes tangle when running. What was envisioned was a way to quickly leash and unleash without having to stop running and mess with a latch as well as keep your hands free when not in use. It had to be compact, light, safe for the dog, and withstand the wear and tear a trail dog would put on it.

The Need

The Solution

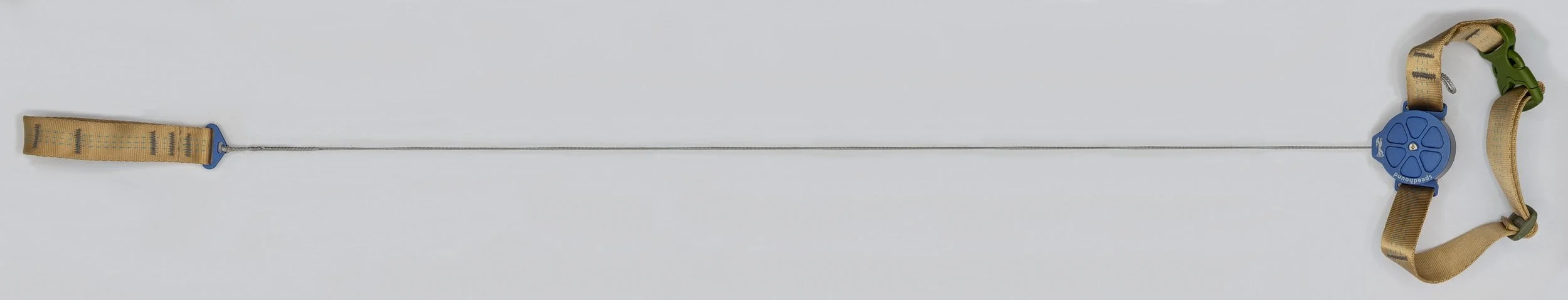

After 2 years of development, testing, and daily use, we have something that fulfills the need we originally set out to address. The SpeedHound leash is simple, light, rugged, and fully serviceable making it the last leash you will ever need for outdoor pursuits. Aside from running, it has become the only leash we use now. Weather hiking, swimming, camping, or traveling the dogs can keep their leashes on without the inconvenience, mess, or risk of a conventional leash that either drags on the ground or ends up misplaced when not in use.

There when you need it, gone when you don’t

Engineered for dogs that run – Compact, lightweight self-retracting leash designed for running with your dogs.

Effortless On/Off Leash Transitions – Don’t stop the run to mess with a conventional clasp and leash. Simply release the handle and the leash will retract into the collar.

Tangle-Free – The SpeedHound design keeps a constant but very light tension on the leash when extended. This prevents the leash from crossing between or tangling in your dogs legs when running.

Leash Free– The SpeedHound design fully retracts when released keeping your hands free. This also keeps the leash from dragging on the ground which results in a frayed and filthy leash outside and a chaotic tangle of ropes inside the house or car.

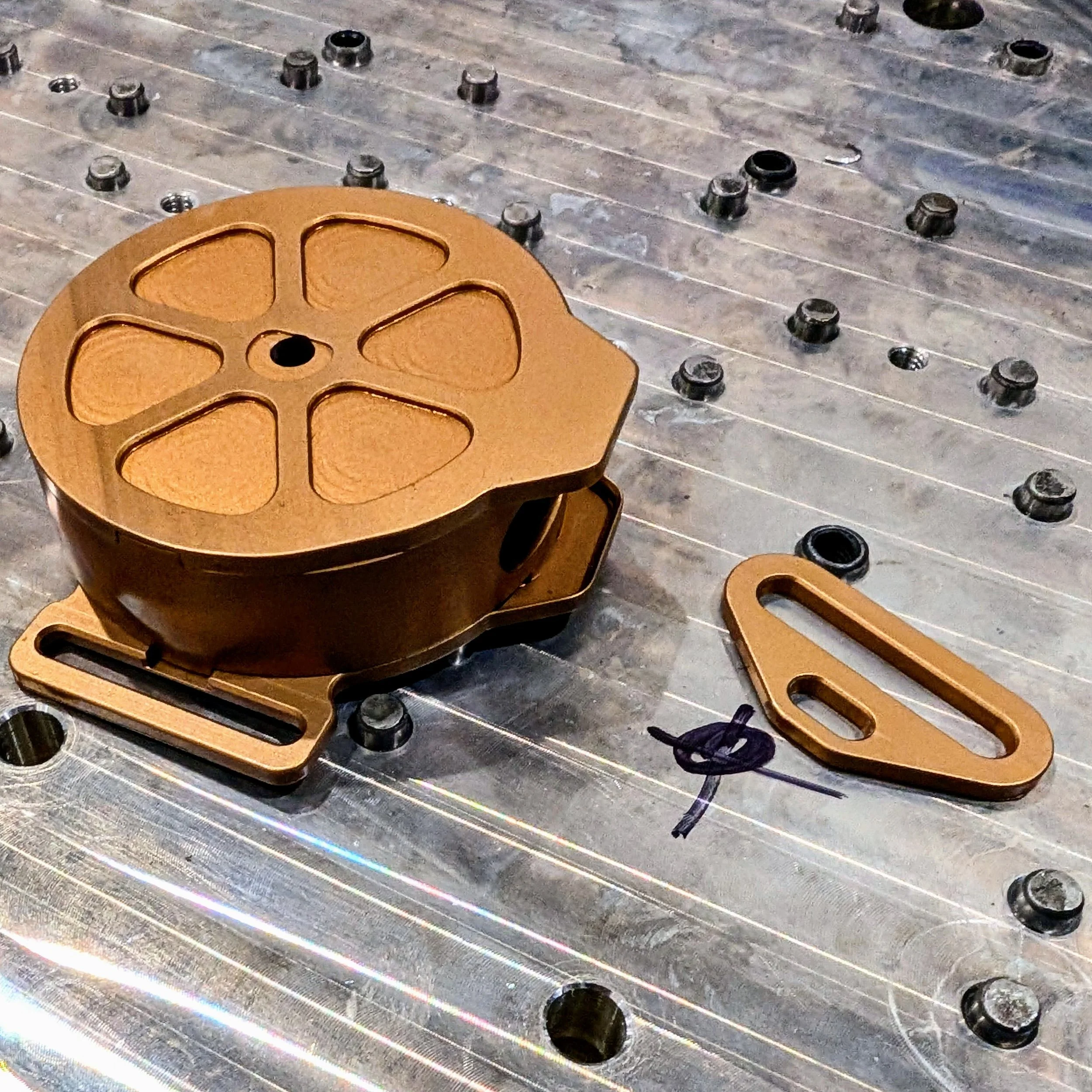

Manufacturing

Manufactured and assembled in Colorado, USA – Materials are brought in as raw stock and are machined, polished, anodized, and assembled in-house.

All American Materials – The Aluminum is from Pennsylvania, the Dyneema cord is produced in Arizona, and the webbing is produced in Georgia.

Minimizing Waste – Minimizing material waste was a key consideration in the design. Aluminum chips created from machining are recycled. The anodizing process was altered to eliminate the use of nickle salts which are commonly used in anodizing and are toxic.

prototype progression from a handle released clasp to an on-collar retractor